Business Sector

> Business Sector > Chemical Additives

> Business Sector > Chemical Additives

Business Sector

Chemical Additives

Corrosion Inhibitor

1Industrial boiler corrosion problem

High temperature corrosion : The alkali minerals and vanadium contained in fuel at industrial boilers produce a covalent mixture of low melting points during combustion, which causes fine corrosion in the boiler.

Low temperature corrosion : The SO3 contained in the fuel comes into contact with moisture on the surface of the heat exchanger at low temperatures in the boiler, resulting in H2SO4 generation and low temperature corrosion.

2Additives type (Mg series)

Oil : Slurry Type

Coral : Water Solubility Slurry

Waste : Water Solubility Slurry

3Effect

Rising a melting point → Fly Ash → High temperature Corrosion Reduction

Reduction Sox → Low temperature Corrosion Reduction

Ash Sintering Suppression → Clinker get soft

4Reference

Before photo of application of company J on Boiler

After photo of application of company J on Boiler

Combustion Improver

1Properties (affiliated with FE)

| Color | Reddish brown liquid |

|---|---|

| Ingredient | Fe series speical mixture |

| Specific gravity | 1.08~1.14g/cm3@15˚C |

| Viscosity | <45mPa·s@20˚C |

| pH | N/A |

| Freezing point | <-20˚C |

| Flash point | >62˚C |

2Reaction mechanism’s effect

Inducing complete combustion by decomposing high molecular weight asphaltenes in fuel.

Combustion Improver is to play role as a source of an oxygen which requires in fuel. It reduces excess O2 amount.

3Reference

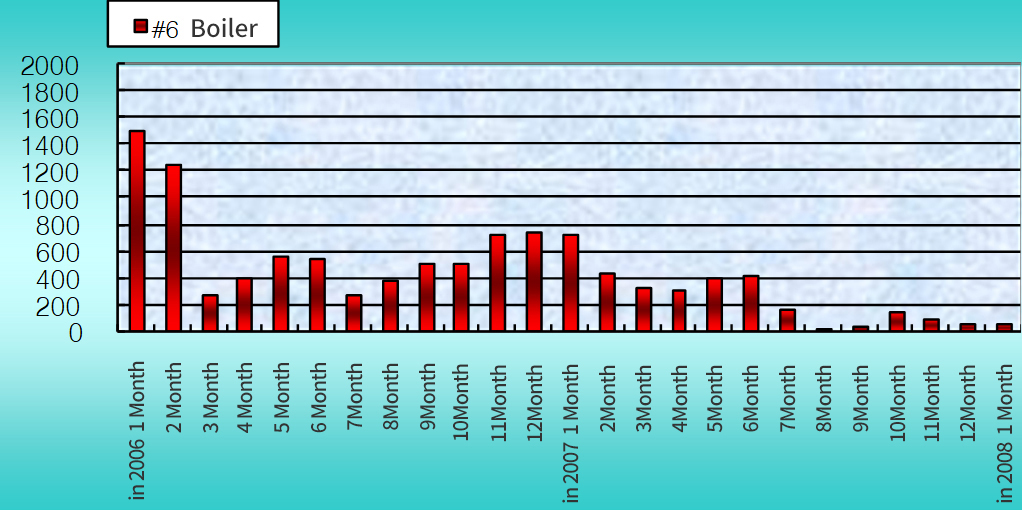

Comparison graph before and after application of company H on amount generated of dust.